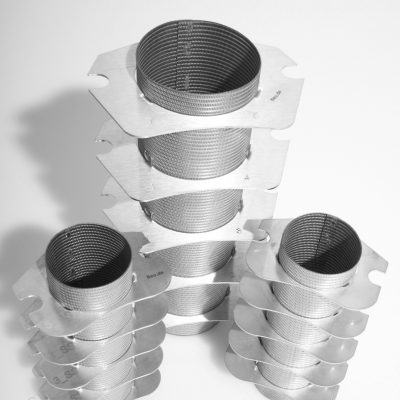

3D-Screens

Dimensions:

We manufacture products from the size of a fingernail up to a side length of 7 metres

Material

In addition to standard stainless steel alloys (1.4301 AISI304, 1.4401 AISI316), we use stainless steels with suitable properties in terms of chemical (1.4404 AISI316L) or thermal strength (1.4841 AISI314) as well as aluminium. Or according to customer requirements.

Tolerances

All products are manufactured to high precision requirements; our benchmark for precision is always the reliable function of our products for the customer - from installation and use to maintenance or servicing; the benchmark for precision is the customer's requirements, alternatively in accordance with ISO2876mK

Product-specific characteristics:

(in addition to dimensions, material(s), tolerances and special features): Contour PM (layers) Finish (e.g. edging)

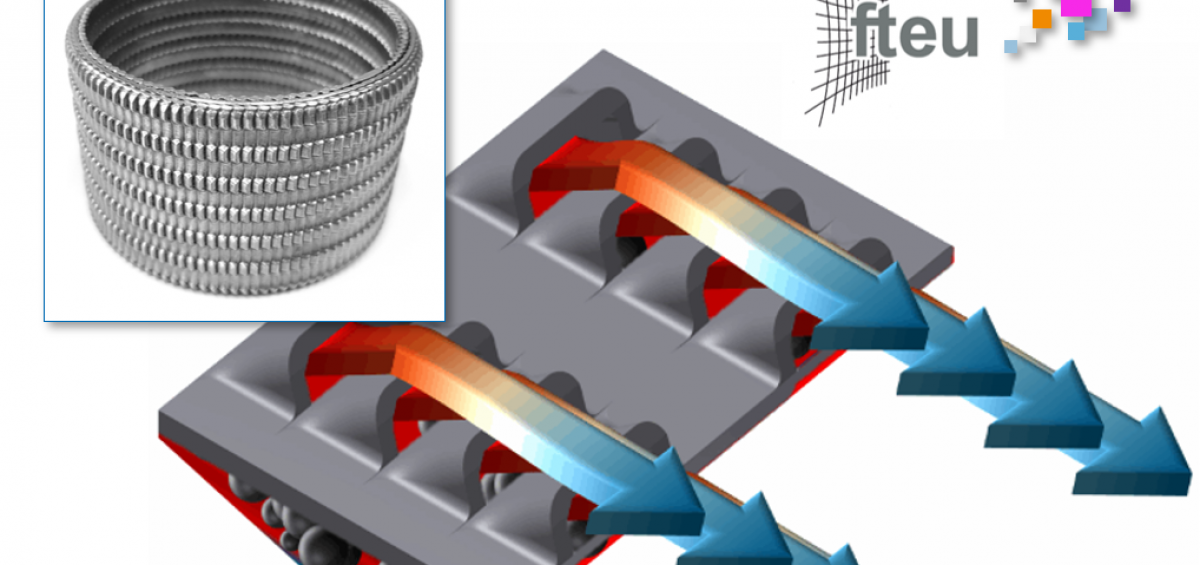

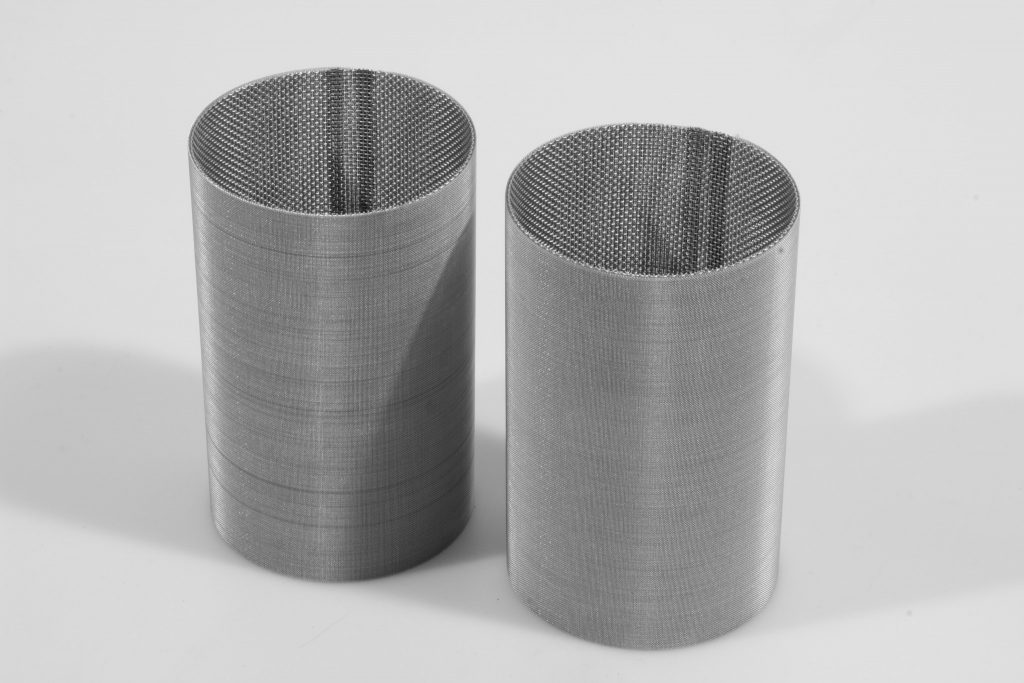

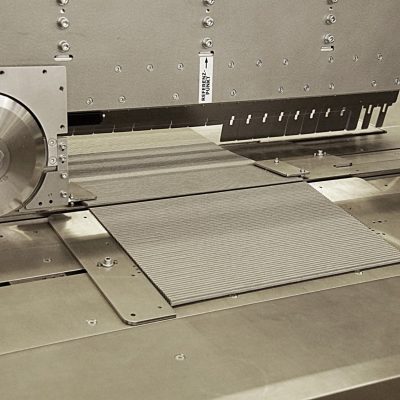

- Shape: flat shape, appearance of a 2D body, the thickness as a 3rd dimension may be created by different layers positioned against each other (and then only act in the 3rd dimension due to the specification of the permeable metal itself); different layers, edging optional

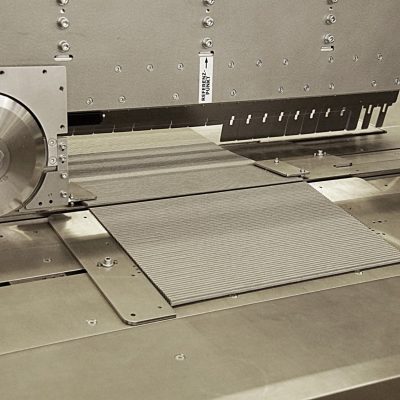

- Production: cutting of the permeable metals to the desired geometry; positioning and fixing of the different layers if necessary; attachment of edging or special features if necessary (critical, precise assurance of precise external dimensions as installation/fit dimensions at the customer)Hardware quality*: precise effective (for installation) external dimensions (thickness and external dimensions at every point and tightly specified); functional integrity/sealing between edging and PM if necessary (for edging)

- Installation: Fitting or clamping in the system of the customer process; orthogonal to the direction of flow

- Flow through: surface is generally flowed through directly (straight); flow in both directions possible in some cases (when cleaning by backwashing)’

Fluid Streams

fteu® 3D-Screens

Gas & Air

Gas process. solutions

Air

process. solutions

- Exhaust air sieve

- Carbon precipitation structures (DAC)

- Protection sieve

Oil & Fuel

Oil/fuel process. solutions

- Hydraulic filter

- Valve filter

- Fuel filter

Water &

low viscous liquids

Water/LV process. solutions

Polymer &

high viscous liquids

Polymer/HV process. solutions

Food & sensitive

fluids and solids

Sens. fluids/solids process. solutions

- Sugar processing filter

- Juice processing filter

- Particle separator

- Solids processing pipe sieve

- Testing sieves

fteu® Permeable Metal Solutions (15 structures; fteu® MASH (i.e. NVH), fteu® D3SM (i.e. auto. gas generator), fteu® Sinter Structures (i.e. seamless solutions), fteu® MircoPleats etc.)

Automotive

Efficient and reliable partner solutions We offer innovative product development and goal-oriented project management for the automotive industry. From hot gas absorbers to oil strainers - our certified processes (IATF 16949) guarantee the highest quality.

Architecture

Aesthetics and functionality combined Our project-specific solutions for buildings combine design with technical functions. From sound-absorbing ceiling elements to heat-resistant partition walls, we offer sustainable, fiber-free products.

Household appliances

Efficient filtration in compact installation spaces We develop tailor-made filter solutions for household appliances that ensure maximum efficiency and quality. Our products offer optimal combinations of cost, function and installation space.

Chemistry

Robust solutions for demanding processes Our filter solutions are tailored to the high chemical and physical requirements in the chemical industry and ensure maximum process stability and product quality.

Plastics

High quality with maximum process efficiency Our filtration and dispersion solutions for the plastics industry support your production processes and guarantee consistent quality and high productivit

Food

Certified filtration for safe processes Our filter solutions for the food industry offer the highest reliability and meet strict quality standards to optimize your processes and reduce costs.

Mechanical and plant engineering

Individual solutions for stable processes We develop tailor-made filter elements that ensure production stability and process quality. Our solutions are precisely tailored to your machines and systems.

Textiles

Optimized filtration for better quality Our filtration solutions for the textile industry ensure high availability and process quality to efficiently manufacture sophisticated products.

Nonwovens

Maximum productivity and quality Our specific filter solutions for nonwoven materials ensure high system availability and process quality. We supply proven products for worldwide applications.

Shipping

Reliable filtration for continuous processes Our standardized filter elements for shipping ensure clean operating materials and reliable performance, no matter where and when.

Medical technology

Precise and reliable filter solutions Our filtration solutions for medical technology offer consistent quality and reliability to optimally support your medical products.

Product Technology

MASH®

- Fiber-free sound insulation and heat absorption

- Higher sound absorption level and explosion protection

fteu® D3SM

- Depth-defined slotted plates for hot gas filtration

- Improved functional variables and power-to-weight ratio

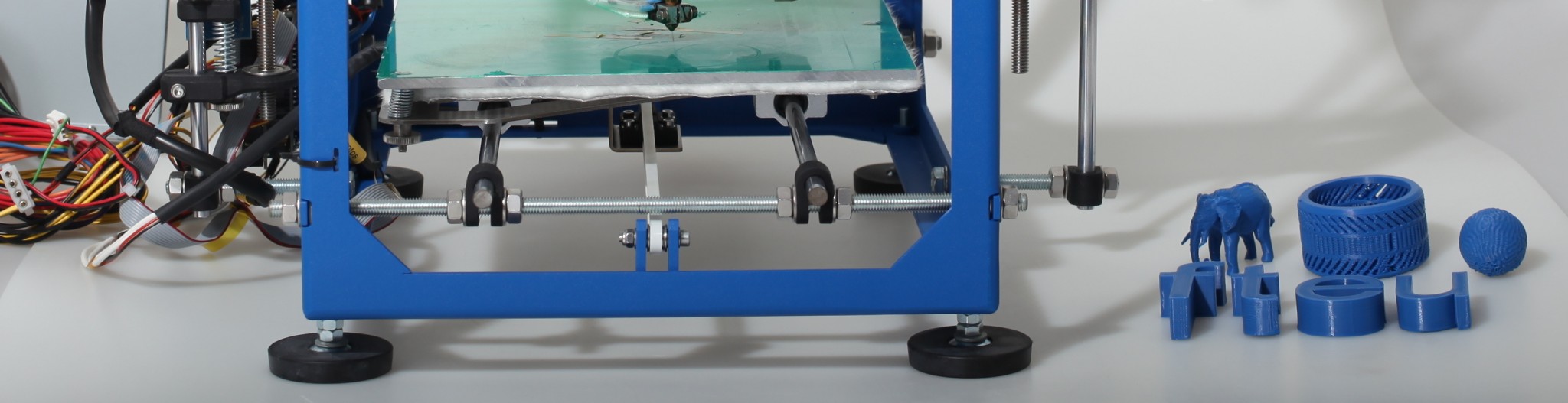

MicroPleats

- Maximum filter area in limited installation space

- Optimized service life and life cycles

Metal mesh

- High-pressure and high-temperature applications

- Combination of wire mesh and metal fiber fleece

Process Technology

Sintering

- Homogeneous sintered structures for filters and phase separators

Pleating

- Increased filter area for longer running times and fewer changes

Joining

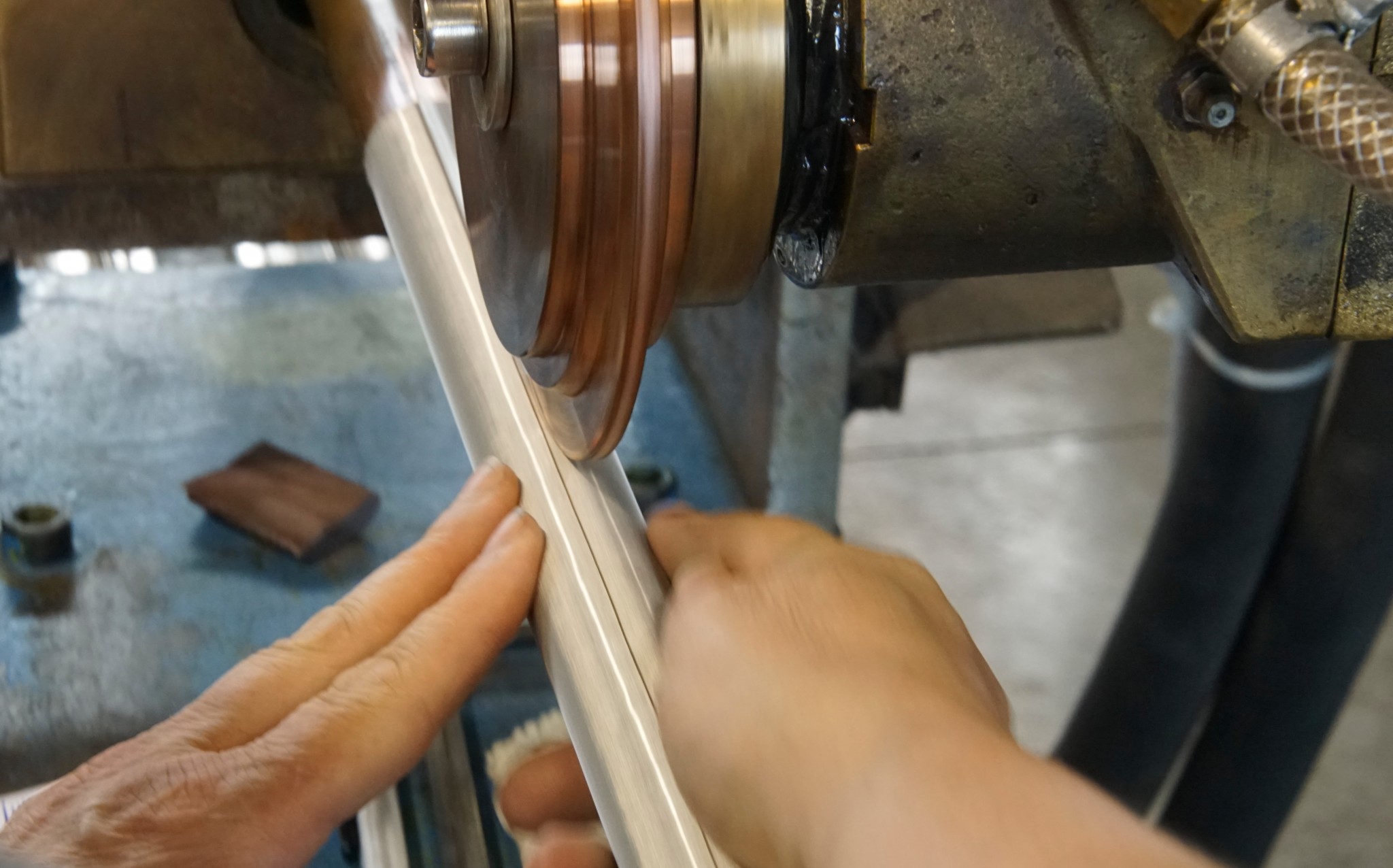

- Precise joining for high quality and technical functionality

Separating

- Optimal cuts for different materials

Engineering

- Development of customer-specific functional elements

Research & Development

- Testing and development of new products and technologies